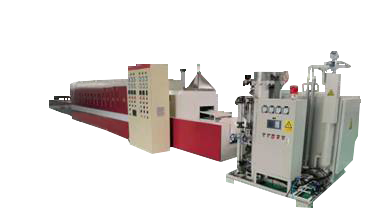

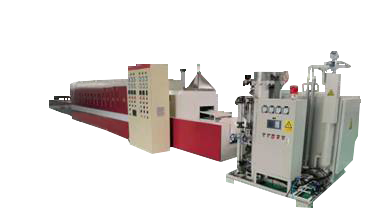

The Atmosphere Furnace is a specialized industrial thermal processing equipment designed for the continuous sintering of powder materials under precisely controlled atmospheres, such as nitrogen. As a high-performance Controlled Atmosphere Furnace, it effectively prevents oxidation during high-temperature treatment, ensuring high density, excellent mechanical strength, and dimensional stability of sintered products.

Compared to traditional batch kilns, this Atmosphere Roller Conveyor Furnace offers superior production efficiency, precise temperature control, and stringent atmosphere management, making it an indispensable part of modern automated manufacturing lines.

Equipment Structure – Optimized for Industrial Atmosphere Sintering

Kiln Body

The kiln body of this Atmosphere Furnace is divided into transition, heating, cooling, and water-cooling zones. The internal roller conveyor system utilizes silicon carbide ceramic rollers, with metal-axle ceramic rollers positioned at both the inlet and outlet sections.

To ensure excellent insulation and airtightness, the kiln is constructed using lightweight mullite refractory bricks and externally lined with ceramic fiber. This design ensures oxygen levels remain below 10 ppm, meeting the stringent requirements of Nitrogen Atmosphere Furnaces.

Atmosphere Control System

This Protective Atmosphere Furnace uses a positive pressure nitrogen atmosphere design, effectively preventing oxygen infiltration during sintering. The nitrogen gas is preheated to improve thermal efficiency and further stabilize the controlled atmosphere conditions.

Cooling System

The cooling zone features multi-point nitrogen gas injection, efficiently cooling the workpieces while preventing oxidation. A serpentine water jacket combined with airflow-assisted cooling further accelerates temperature reduction, meeting the fast-paced demands of continuous atmosphere sintering furnaces.

Heating System

Heating is achieved through quartz tubes embedded with iron-chromium-aluminum alloy (FeCrAl) heating wires, ensuring uniform heating across the work zone. The system uses multi-zone proportional control for accurate temperature management, essential for high temperature atmosphere furnace operations.

Temperature Control System

Equipped with PLC automation, touchscreen interface, and advanced temperature control modules, this Industrial Atmosphere Furnace uses K-type thermocouples for real-time temperature feedback. Additional safety features include over-temperature protection and continuous data recording via a paperless recorder, ensuring process traceability.

Conveying System

The ceramic roller chain transmission system provides adjustable speed control from 0 to 300 mm/min, ensuring stable and reliable product transfer through each temperature and atmosphere zone.

Key Technical Parameters

| Parameter | Description |

|---|

| Kiln Width | Customized per client requirements |

| Conveyor Speed | 0–300 mm/min (continuously adjustable) |

| Rated Temperature | 700–1200°C |

| Maximum Temperature | Up to 1200°C |

| Sintering Atmosphere | Nitrogen |

| Heating Elements | FeCrAl heating wire / silicon carbide rods |

| Heating Zones | Customized based on application |

| Temperature Display Accuracy | ±0.1°C |

| Temperature Fluctuation | ≤ ±5°C |

| Temperature Uniformity | ≤ ±5°C (no load) |

| Heating Rate | ≥ 5°C/min |

| Outer Shell Temperature | ≤ ambient + 15°C; joints ≤ ambient + 40°C |

| Power Consumption | Depends on design specifications |

Product Features

Continuous Operation: The ceramic roller conveyor system enables uninterrupted, high-efficiency sintering, making this Atmosphere Sintering Furnace ideal for mass production lines.

Excellent Atmosphere Sealing: The independent sealing design between the heating and transmission chambers ensures oxygen levels stay below 10 ppm, preventing product oxidation during sintering.

Precise Temperature Control: Multi-zone proportional temperature regulation delivers outstanding uniformity and minimal fluctuation, crucial for critical sintering processes.

Efficient Cooling System: The integration of nitrogen gas injection and water-cooling technologies ensures rapid cooling, reducing overall cycle times.

Energy Saving & Environmentally Friendly: Using high-performance insulation materials, the furnace significantly reduces heat loss and operational energy consumption.

User-Friendly Operation: Intelligent PLC control with a touchscreen interface allows easy operation, real-time monitoring, and multi-level safety alarms.

Easy Maintenance: The modular design with quick-replaceable ceramic rollers simplifies maintenance and reduces downtime.

Wide Application Scope: Suitable for powder metallurgy, electronic ceramics, lithium battery materials, magnetic materials, glass-ceramics, and new energy material sintering.

Application Areas

Electronic Ceramics Sintering: Used for multilayer ceramic capacitors (MLCC), ceramic substrates, and other high-tech ceramic products.

Powder Metallurgy: Continuous sintering of powdered metals to improve part density and mechanical properties.

Lithium Battery Materials: Heat treatment and sintering of cathode, anode, and separator materials.

Magnetic Material Manufacturing: Processing soft and hard magnetic materials with improved magnetic performance.

Glass-Ceramics: Rapid sintering of glass-ceramic components.

New Energy Materials: Fuel cell ceramics and other advanced materials requiring controlled atmosphere sintering.

Frequently Asked Questions (FAQ)

Q1: What types of materials can be sintered in the atmosphere furnace?

A1: The furnace is suitable for oxidation-sensitive powder materials such as ceramic substrates, powder metallurgy components, electronic ceramics, and lithium battery materials.

Q2: How does the furnace maintain the purity of the sintering atmosphere?

A2: Through high-quality sealing between the heating chamber and transmission chamber, positive pressure nitrogen atmosphere, and nitrogen gas cooling of ceramic rollers, oxygen infiltration is prevented, keeping oxygen content below 10 ppm.

Q3: What is the maximum operating temperature of the furnace?

A3: The maximum operating temperature can reach up to 1200°C, suitable for most high-temperature sintering processes.

Q4: Is the conveyor speed adjustable?

A4: Yes, the conveyor speed can be continuously adjusted from 0 to 300 mm/min via a variable frequency drive to accommodate different sintering durations.

Q5: Does the furnace support automated control?

A5: Absolutely. The furnace integrates PLC control with touchscreen interface, enabling automatic regulation of temperature, atmosphere, and conveyor speed, along with safety alarms.

Q6: What about energy consumption?

A6: The furnace uses advanced insulation and high-efficiency heating elements to minimize energy consumption while maintaining stable operation.