The Steam Tunnel Oven is a continuous heating system that uses steam as its primary heat source. This advanced equipment is widely applied in various industries including food processing, pharmaceutical manufacturing, chemical engineering, and electronics, where it serves critical roles in drying, sterilizing, pre-cooking, and curing different types of materials.

Dual Heating Modes: Contact and Non-Contact Steam Heating

Our steam tunnel Ovens are designed with two flexible steam heating modes, each suited for different material types and process goals:

Contact Steam Heating

Steam is directly injected into the tunnel chamber, where it comes into direct contact with the product, ensuring rapid and uniform temperature rise. This method is especially effective for applications that demand high thermal efficiency in minimal time.

Non-Contact Steam Heating

Steam flows through a heat exchanger to transfer thermal energy to the surrounding air, creating high-temperature hot air. This hot air is then circulated inside the Oven, delivering consistent, indirect heating to the material. Hot air recycling significantly improves energy efficiency and supports sustainable operation.

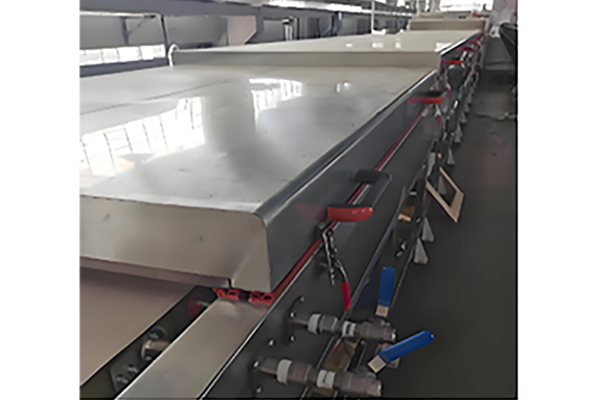

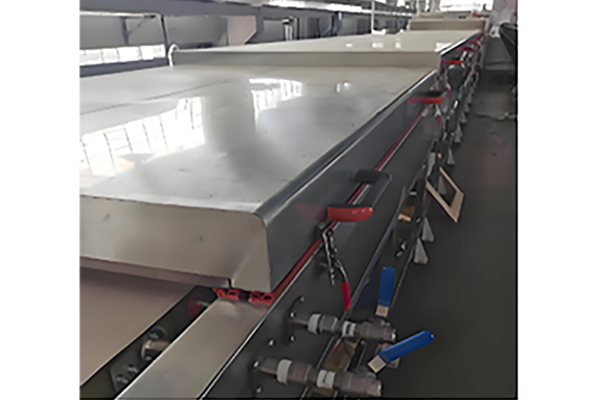

Core Components of the Steam Tunnel Oven

| Component | Description |

|---|

| Tunnel Chamber | Constructed with advanced insulation materials such as rock wool or polyurethane, effectively minimizing heat loss and maintaining stable internal temperatures. |

| Steam Heating System | Powered by an external industrial boiler, steam is transported via insulated pipelines to the oven chamber, maintaining a continuous and adjustable steam supply. |

| Conveyor System | Available in various configurations—mesh belt, cloth belt, chain plate, steel belt, or roller conveyor—to suit different product sizes, shapes, and process requirements. Conveyor speed is adjustable to match specific processing durations. |

| Temperature Control System | Equipped with real-time temperature sensors, the system automatically regulates steam flow, fan speed, and conveyor movement to ensure precise temperature control and consistent product quality. |

Technical Specifications

| Parameter | Specification |

|---|

| Temperature Range | 50°C – 200°C (Dependent on steam pressure: 0.1–0.8 MPa = approx. 120–170°C) |

| Tunnel Length | Customizable: Common lengths range from 3 to 30 meters based on production capacity |

| Conveyor Speed | Adjustable from 0.1 to 5 m/min |

| Steam Consumption | Depends on equipment size and temperature; typically ranges from several kilograms to hundreds of kilograms per hour |

| Power Requirement | 5 – 50 kW (for blower motors, conveyor drive motors, and control systems) |

Key Advantages

Continuous & High-Efficiency Operation: Ideal for large-scale industrial applications with continuous product flow.

Energy Saving & Eco-Friendly: Optional hot air recycling and insulation reduce operating costs and carbon footprint.

Flexible Design Options: Customizable tunnel length, belt type, and control system configuration.

Precise Temperature Control: Enables fine-tuning of process parameters for sensitive or high-value materials.

Wide Industry Applications: Adaptable for use in multiple fields, supporting diverse production needs.

Applications in Various Industries

The steam tunnel oven can be tailored for specific industry uses, including:

Food Industry: Sterilizing packaged goods, pre-cooking meat or vegetables, drying snacks and processed foods.

Pharmaceuticals: Moisture removal, packaging sterilization, or tablet drying.

Packaging: Steam tunnel for shrink sleeve labeling on PET bottles, glass jars, or cosmetic containers.

Chemical & Electronics: Heat curing of materials, drying chemical components, or dehumidifying electrical components.

Frequently Asked Questions (FAQ) About Steam Tunnel Ovens

What is a steam tunnel oven?

A steam tunnel oven is a continuous heating device that uses steam as its heat source. It is commonly used for drying, sterilizing, curing, and pre-cooking materials in industries such as food processing, pharmaceuticals, chemicals, and electronics.

What are the heating methods used in a steam tunnel oven?

There are two primary heating methods:

Contact Steam Heating: Steam is directly injected into the tunnel to make direct contact with the material, ensuring fast and efficient heat transfer.

Non-Contact Steam Heating: Steam passes through a heat exchanger to heat air, forming hot air circulation inside the tunnel, suitable for products that require indirect heating.

What industries commonly use steam tunnel ovens?

Steam tunnel ovens are widely used in:

Food processing: drying vegetables, pre-cooking meat, sterilizing packaged products

Pharmaceutical industry: moisture removal and sterilization of medicines or packaging

Chemical industry: drying powders and heating sensitive materials

Electronics: drying electronic parts or curing adhesive compounds

Packaging: shrink sleeve labeling on PET bottles or containers

Can the steam tunnel oven be customized?

Yes. We offer customized steam tunnel ovens according to your production line requirements, including:

Tunnel length

Conveyor type (mesh belt, chain plate, roller, etc.)

Heating mode (direct or indirect steam)

Temperature control system

Steam input configuration

What is the typical operating temperature range?

The temperature range is 50°C to 200°C, depending on the steam pressure:

What are the typical conveyor speeds?

The conveyor speed is adjustable, typically ranging from 0.1 to 5 meters per minute, depending on the required processing time for your material.

How much steam does the oven consume?

Steam consumption depends on the size of the tunnel, temperature setting, and process duration. It typically ranges from several kilograms to hundreds of kilograms per hour.

What is the power requirement for operating the machine?

The machine itself doesn't use electricity for heating (as steam is the heat source), but power is required for fans, control systems, and conveyors—typically between 5–50 kW depending on the model and configuration.